|

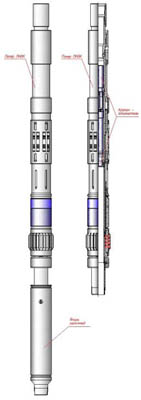

Packer Packer

Purpose:

To divide the barrel casing, productive layer protection from exposure to the working environment in the process of holding various technological operations, to repair and replace equipment landing without killing the well.

Scope:

For oil wells equipped with ESP, screw and rod pumps.

Features:

- Integrated packer device has included:

- packer type PMEK;

- valve cutter;

- puller;

- sand anchor (on demand).

- The packer is set in the casing by a mechanical rotation to the right and is in operation for a long time and is not associated with the tubing.

- Oil flowing from the reservoir into the working top packer zone is cleared of solids, that extends the turnaround time of the pump.

- Valve cutter allows to make SPO equipment without killing the well, excludes additional impact on the reservoir. Opening-closing valve is automatic pressure drop.

- Valve cutter inside the packer with necessity of different manufacturing operations extracted stripper down on the column rods put back.

- Anchor packer device placed inside the body and prevents premature release.

- Packer provided with a mechanism that prevents the emergence of torque at the left rotation and reduces stress breakloose rotation to the right.

- The packer is set in a given interval by simple rotation to the right without additional load weight tubing with an effort 150 kgm. Connector with the tubing occurs when rotation to the right and cutting the pin.

- Dismantling of the packer occurs equipped with a by pulling string puller with an effort no more than 10t.

- Operating packer temperature is 150°C. For additional application can be completed sealing element for temperature up to 200oC.

Advantages:

- The high degree of reliability of sealing the casing with a long service life.

- Perceives a high pressure drop - up to 20 MPa.

- Enables the operation at extremely high temperatures.

- Performs cleaning extracted liquid from the solids than overhaul extends the life of ESP and other pumps.

- Retrievable valve cutter allows to remain a packer in a mode of regular operation for a long time.

- Removing the valve is made by using the column rods eliminates the additional lowering tubing. At the same time makes it easier repairing or replacement of the valve unit.

- The ability to perform the necessary processing operations to near wellbore area, without removing the packer.

- The ability to perform tripping of equipment to repair wells without jamming.

- The ability to produce depressurization wellhead to replace or repair valves gland cable entry without killing the well.

- Does not require pre-cleaning before installing casing packer.

Specifications

1. Packer

| TYPE | Nominal diameter of casing, mm | Max. pressure drop across the packer, MPa | Operating temperature range, ° C | Max. outer diameter, mm | Diameter of the channel, mm | Max. torque of packer, kgm | Max. axial load removal packer ts |

| PMEK114-15 |

140 |

20 |

150 (200) |

114 |

50 |

150 |

10 |

| PMEK118-15 |

146 |

118 |

| PMEK140-15 |

168 |

140 |

2.Valve cutter

| TYPE | Nominal diameter of column, mm | The pressure valve closing, MPa | Cracking pressure, MPa | Operating temperature, ° C | Dimensions |

| Outer diameter, mm | Height, mm |

| PMEK114-15КО |

140 |

0,7-0,9 |

2,5-3,5 |

150 |

54 |

600 |

| PMEK118-15КО |

146 |

0,7-0,9 |

2,5-3,5 |

150 |

54 |

600 |

| PMEK140-15КО |

168 |

0,7-0,9 |

2,5-3,5 |

150 |

54 |

600 |

3. Sand anchor

| TYPE | Nominal diameter of column, mm | Max. ext. diameter, mm | The inner diameter of the barrel, mm | Max. production rate, tons / day | Max. contains. solids, g/l | Min. size of mechanical particle confined anchor |

| YAP-114-25 |

140; 146; 168 |

114 |

40 |

100 |

23 |

0,1 |

|